Top Aluminum Foil Manufacturer in China – Your Trusted Supplier for Food, Pharma, and Industrial Foil Solutions

News&Blogs

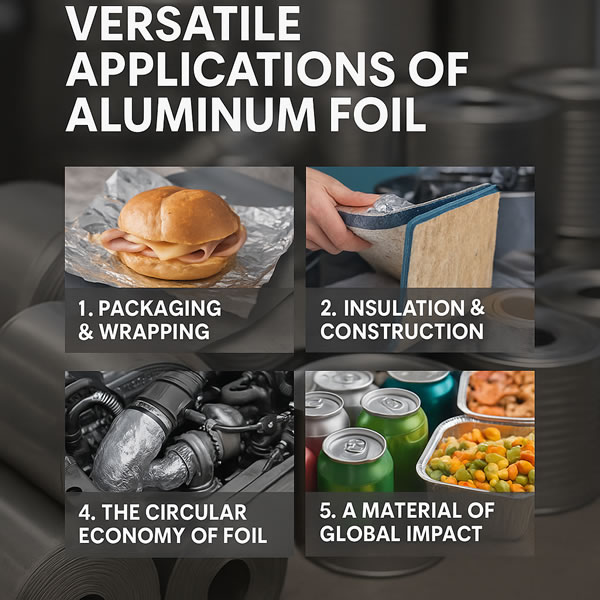

aluminum foil applications across packaging, insulation, and industrial sectors.

The Versatile Applications of Aluminum Foil

PRODUCT DESCRIPTION

Aluminum foil is not just a packaging material—it is a high-performance, adaptable component used across industries. Its functionality, lightweight profile, and environmental advantages have made it a critical solution in modern manufacturing and engineering.

1. Packaging & Wrapping

One of the most widespread uses of aluminum foil is in the packaging sector, especially in food and pharmaceutical industries.

Food Freshness: Aluminum foil is an ideal material for preserving food quality and extending shelf life. Its non-permeable structure keeps out light, oxygen, and moisture.

Tamper Resistance: In medical packaging, such as blister foil, it ensures sterility and easy detection of any compromise.

Convenient Formats: Rolls, trays, and laminates make it compatible with automated packaging systems for efficient, large-scale operations.

Thanks to its formability and safety compliance, aluminum foil is trusted for everything from candy bars to hospital-grade medication sealing.

2. Insulation & Construction

Aluminum foil’s reflectivity and low emissivity make it a natural choice for thermal insulation.

Building Applications: Foil-faced insulation boards or reflective roof panels reduce heat gain or loss, helping maintain energy efficiency in homes and commercial buildings.

HVAC Duct Wrapping: Foil improves air system efficiency by limiting thermal loss and protecting against moisture buildup.

Acoustic Dampening: When combined with other layers like foam or fiberglass, foil enhances soundproofing in walls and flooring.

The material’s flexibility and resistance to corrosion make it a strong long-term performer in construction environments.

3. Industrial & Automotive Use

Aluminum foil plays an unseen but essential role in a wide range of industrial processes.

Capacitors and Transformers: Electrical-grade aluminum foil serves as a conductor in capacitors and energy storage devices.

Automotive Shielding: Modern vehicles use foil in thermal shields, engine wraps, and battery packs to manage heat and protect electronics.

Lightweight Engineering: Foil’s minimal weight helps reduce total vehicle mass, contributing to better fuel efficiency and emissions control.

Its thermal, electrical, and chemical resistance makes foil indispensable in precision systems.

4. The Circular Economy of Foil

An essential reason for aluminum foil’s expanding usage is its alignment with sustainable manufacturing goals.

100% Recyclable: Aluminum can be recycled repeatedly without loss of performance or purity.

Low Carbon Potential: Recycling foil requires just 5% of the energy needed to produce primary aluminum, making it ideal for eco-conscious applications.

Sustainable Packaging Demand: As global regulations crack down on plastic waste, more manufacturers are turning to recyclable foil solutions.

As sustainability becomes a market differentiator, aluminum foil’s recyclability has become a major selling point.

5. A Material of Global Impact

The global footprint of aluminum foil continues to grow rapidly.

Food Sector: Demand for convenience and frozen foods is pushing up usage of foil trays, pouches, and sealing lids.

Pharma Growth: As global access to medication rises, blister foil consumption expands in both developed and emerging markets.

Construction Boom: Rising temperatures and energy costs are fueling the adoption of reflective foil insulation in Asia, the Middle East, and Africa.

In 2024, over $30 billion USD worth of aluminum foil products were sold globally, with an average annual growth rate above 6%.

Final Takeaway

Whether protecting a sandwich, insulating a rooftop, or shielding a lithium battery, aluminum foil adapts across industries. Its combination of barrier performance, lightweight design, and recyclability has made it one of the most future-ready materials in global manufacturing.

Why Us

Premium-Grade Aluminum Foil

Premium-Grade Aluminum Foil

Comprehensive Aluminum Foil Solutions Tailored to You

-

Innovative Foil Design Tailored

We have professional aluminum foil packaging designers who develop 200+ new foil packaging structures every month. We can create the best custom foil solutions for your brand. -

Premium Aluminum Foil Quality

With extensive expertise in aluminum foil manufacturing, packaging design, and application solutions, we’ve supported more than 1,000 clients across the globe. -

Best Value Aluminum Foil

We are located in one of China’s key aluminum industry hubs, with access to lower-cost raw materials. With the same high quality, our prices are significantly more competitive. -

Aluminum Foil Testing Services

Our aluminum foil products undergo multi-level quality control, along with comprehensive material and performance testing.

Get in Touch Today – Start Your Custom Aluminum Foil Project

Contact UsFocused on Custom Aluminum Foil Development for Global Packaging Brands...

Blog And News

The Versatile Applications of Aluminum F···

2025-05-23 Aluminum foil is not just a packaging material—it is a high-performance, adaptable component used across industries. It··· Read More>>Understanding Aluminum Foil: Key Propert···

2025-05-23 Aluminum foil is far more than a kitchen essential — it is a cornerstone material in modern packaging, insulation, medi··· Read More>>Aluminum Foil: What You Need to Know

2025-05-23 Aluminum foil is one of the most versatile and widely used materials in modern packaging, insulation, and industrial app··· Read More>>